Services

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore ex ea commodi.

Capacity Machining Range

1/16” – 12” Dia

Tolerance

.0002

Production Volume

1 – 1m+

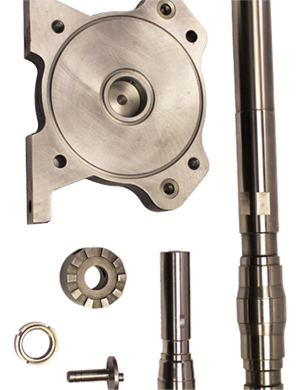

Screw Machining

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium.

- CNC Swiss

- Single Spindle

- Multi-Spindle

cnc Machining

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium.

- Turning

- Milling

- Grinding

- I.D.

- O.D

secondary

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium.

- Broaching

- Drilling

- Tapping

Assembly

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium.

- One

- Two

- Three

Tool Making

For single & multi-spindle automatic screw machines. aperiam, eaque ipsa quae ab illo inventore.

- High Speed Cutting

- Carbide Cutting

Inventory Management

For single & multi-spindle automatic screw machines. aperiam, eaque ipsa quae ab illo inventore.

- One

- Two

equipment

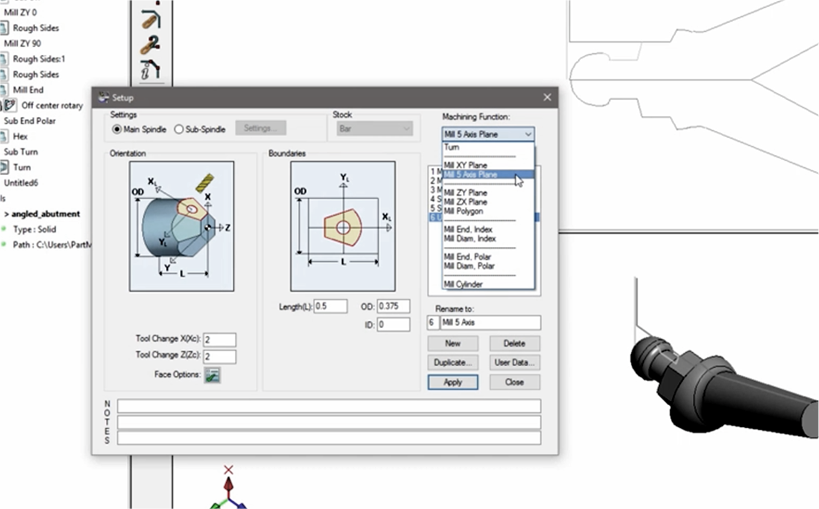

CNC

CNC

Our CNC-Swiss machines have sub spindles, live tooling & multiple attachment capabilities. All CNC-Swiss turning centers are equipped with high pressure coolant pumps and 12 ft. FMB/Iemca bar loaders. All machines run first shift and certain designated machines can run night and weekend “lights out” shifts, if job application allows.

Single-Spindle

Our CNC-Swiss machines have sub spindles, live tooling & multiple attachment capabilities. All CNC-Swiss turning centers are equipped with high pressure coolant pumps and 12 ft. FMB/Iemca bar loaders. All machines run first shift and certain designated machines can run night and weekend “lights out” shifts, if job application allows.

Multi-Spindle

Our CNC-Swiss machines have sub spindles, live tooling & multiple attachment capabilities. All CNC-Swiss turning centers are equipped with high pressure coolant pumps and 12 ft. FMB/Iemca bar loaders. All machines run first shift and certain designated machines can run night and weekend “lights out” shifts, if job application allows.

Grinding

Our CNC-Swiss machines have sub spindles, live tooling & multiple attachment capabilities. All CNC-Swiss turning centers are equipped with high pressure coolant pumps and 12 ft. FMB/Iemca bar loaders. All machines run first shift and certain designated machines can run night and weekend “lights out” shifts, if job application allows.

Secondary Operations

Our CNC-Swiss machines have sub spindles, live tooling & multiple attachment capabilities. All CNC-Swiss turning centers are equipped with high pressure coolant pumps and 12 ft. FMB/Iemca bar loaders. All machines run first shift and certain designated machines can run night and weekend “lights out” shifts, if job application allows.

Outside Services

Our CNC-Swiss machines have sub spindles, live tooling & multiple attachment capabilities. All CNC-Swiss turning centers are equipped with high pressure coolant pumps and 12 ft. FMB/Iemca bar loaders. All machines run first shift and certain designated machines can run night and weekend “lights out” shifts, if job application allows.

Testing

Our CNC-Swiss machines have sub spindles, live tooling & multiple attachment capabilities. All CNC-Swiss turning centers are equipped with high pressure coolant pumps and 12 ft. FMB/Iemca bar loaders. All machines run first shift and certain designated machines can run night and weekend “lights out” shifts, if job application allows.

commitment to quality

Quality Assurance functions at RGD Technologies are based upon an ISO 9001:2015 Quality Management System (QMS). The QMS covers all facets of the operation and is supported by documented procedures focused on meeting our customer’s requirements. Our internal audit system evaluates and determines its effectiveness. Additionally, a fully integrated ERP system provides a solid backbone for quality interface with all other daily business functions, and helps provide full transparency to part and lot traceability.