OUR FACILITY

- Plant Location: 50 Emmett St., Bristol, CT 06010

- Plant size: 200,000 Sq. Ft.

RGD Technologies is an owner-occupied facility. Our manufacturing operations are fully air-conditioned/heated and house premium air filtration systems that improve air quality and working climate while generating environmental benefits. We actively engage in energy saving plans and initiatives that result in both eco-friendly and cost savings opportunities.

A multitude of equipment and diversified capabilities allow the flexibility to:

- Accommodate quote packages with a variety of different part volume and material requirements

- Satisfy low to high volume range requirements for parts, which is especially appealing to customers vulnerable to extreme fluctuations in usage or seasonal requirements for products

- Run high volume orders on multiple machines, if needed, to meet weekly usage numbers

- Run parts in different work areas, if necessary, if volumes change considerably (up or down) over time

We work together with you to set up optimal economic order quantities for your EAU’s in order to establish most favorable cost breaks. This can be married with a stocking program or blanket purchase order, or simply apply to discrete, order-as-needed items.

EQUIPMENT

CNC-Swiss Machining Centers

- (28) CNC-Swiss Tsugami Turning Centers (1/16” to 1-1/2” Capacity)

-

- Concentrated capital expansion & growth efforts in our CNC Swiss machining area since 2011 has shaped a state-of-the-art CNC Swiss department. Growth from three to nineteen machines between 2011-2013, and additional ten machines added between 2014-2018.

- Expansion plans are on-going, as needs and contracts arise to add more equipment.

- Our CNC-Swiss machines have sub spindles, live tooling & multiple attachment capabilities.

- All CNC-Swiss turning centers are equipped with high pressure coolant pumps and 12 ft. FMB/Iemca bar loaders.

CNC-Lico Machining Centers

- (2) Lico 1-5/8” LNT42s

Multi-Spindle / Davenport & Acme

- (50) Davenport Model B (up to 7/8” Capacity)

- ( 2) 8-Spindle Acme-Gridley machines (7/16” to 2-5/8” Capacity)

Single Spindle / Brown & Sharpe

- (99) Brown & Sharpe Single-Spindle Automatics (1/16” TO 2-3/8” Capacity)

CNC Machining / Okuma, HAAS, Weldon

- CNC Turning, Milling, Grinding

Centerless Grinding

- (5) Cincinnati Centerless Grinding Machines; (2) with Automatic Bar Loaders

In-house ability to grind our own Bar Stock for materials falling within the noted capacity ranges, holding tolerances as close as .0002. We can also grind parts in-house to maintain tight tolerances and meet more stringent customer blueprint requirements, when required.

Secondary Operations

- Broaching, Milling, Drilling, Assembly, and Vibratory functions.

Absolent Premium Air Filtration System

OUTSIDE SERVICES

RGD Technologies Corp. utilizes approved outside suppliers for the following services:

- Plating

- Heat Treating

- Black Oxide

- Passivation

- Bright Dip

- Anodizing

- Burnishing

- Coatings (Teflon, Phosphate, Tungsten)

- Thread Patch

- Injection Over Molding

- Painting

- Welding

- Centerless Grinding (if beyond our in-house capabilities)

RAW MATERIALS

We process various types of materials and sizes in round, square, hex and rectangular configurations.

COMMON RAW MATERIAL GRADES:

- Steel: 1010/1020 tubing, 1018, 1117, 1141, 1144, 12L14, 1215, 4130, 4140, 41L40, 6150, 8620, 9310 & W1 drill rod

- Stainless: 17-4PH, 302, 303, 304, 316, 347, 416, 430 & 440

- Aluminum: 2011-T3, 2024-T4, 6061-T6 & 7025

- Brass: 353, 360

- Copper (ETP, Tellurium): 110, 145

- Bronze: 314, 544 & 655

- Plastic: Nylon, Delrin, Teflon & Phenolic

- Special Alloys: Titanium, A286, Monel

- Castings and extruded parts

We quote parts complete with supply of material or can manage programs with customer supplied material. All Customer Supplied Material is handled, labeled, and stored according to our documented QMS.

ENGINEERING

To assist in the layout process, our engineering capabilities include:

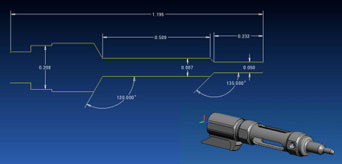

- PartMaker programming software: Lathe, Mill and Swiss, version 2014, featuring advanced 3D machining simulation and solid modeling.

- Servo Cam

- Extreme DNC Network

INSPECTION/TESTING

Key State-of-the-Art Measuring and Test Equipment include:

Key State-of-the-Art Measuring and Test Equipment include:

- Mitutoyo: Elf Quick Vision Inspection System with optic and touch probe capabilities

- Mitutoyo: Contracer 2000-Surface/Contour Measuring Inspection System

- Additional large range o f industry standard M&TE

CUSTOMER SERVICE

RGD Tech’s Sales and Customer Service team are the front-line representatives whose primary focus is accommodating the needs of your business. Our service associates are hands-on and dedicated to maintaining direct and professional communication with customer contacts at all levels. Daily customer service interactions remain the responsibility of our Account Managers.

Management is involved at all sales levels, with sales accountability shared by our President, Director of Business Development, Operations Manager, and outside sales representatives, as required. Upper management drives all sales initiatives, including quotation package execution and transition, contract negotiations, and cost incentive programs, to name a few.

Account Managers

Every customer is assigned an internal Account Manager who is the primary contact from within our companies. All RFQ’s, quotations, purchase orders, expedite questions, etc. flow through the Account Manager. As necessary, the Account Manager takes responsibility for directing inquiries to other contacts within RGD Tech to obtain needed information, but always remains in the loop. This setup facilitates communication and helps streamline correspondence.

We work closely with you to help take your program to the next level, managing many of your needs for you. Our experienced internal customer support team becomes a reliable extension of your business, especially with respect to Inventory Management or Special Contractual programs that may be in place.

Our manufacturing, quality and customer service departments excel not only at fulfilling our customers’ demands, but anticipating their needs through regular and frequent communication. We strive to learn the intricacies of our customers’ businesses, therefore becoming a critical extension of their operating entity.

Inventory Management Programs

RGD Technologies Corp. is proficiently experienced at managing many different types of Inventory Programs with our customers, including:

- VMI (Vendor Managed Inventory)

- Kanban

- JIT

- Consignment

Program agreements with our customers typically outline

- Min-Max inventory requirements

- MOQ’s

- Optimum box quantities (based on usage, MOQ’s and box weight limits)

- Inventory liability commitments and time frames for release of inventory

We can also accommodate

- Customized Packaging requirements

- Bar Coding

- Specialized label requirements

- Order Management via Customer Portals

These types of programs add value by allowing us to support our customers’ requirements via daily and weekly review of supplier schedules and forecasts. We can therefore integrate customer visibility into our review of purchase order commitments vs. actual historical usage and inventory on hand, and trigger production replenishment or flag potential customer reorder requirements, as needed.

Optimum program effectiveness occurs via thorough and timely communication between our Account Managers and our customer Purchasing and Planning contacts.

Rounding out final delivery implementation is a well-trained and effective Shipping and Receiving team. Besides the normal shipping/receiving functions, here at RGD TECH our Shipping department is a critical extension of our Production Control department, being accountable for final work flow counts, outside service transactions, inventory transactions/cycle counts, labor ticket entry and some expediting tasks… all of which help contribute to an effective overall inventory management program.